Digital twins: what are they and what are their benefits for the industry

Everything is digitally replicable: cars, factory components, the most modern cities, energy distribution to the parts that make up our body. This is thanks to modern technology that drives the development of various industries and sectors around the world: digital twins.

For example, in the famous Formula 1 races, this technology is already implemented to improve the imposing race cars. Also DHL, the renowned postal parcel delivery company, has created a digital map of its warehouses and supply chains with the aim of being more agile and optimizing delivery times. On the other hand, megacities such as Shanghai or Singapore have digital twins to design better buildings, public transport systems, as well as prevent pollution from their streets and avenues.

Hundreds of companies and industries already have their eyes on this modern technology. A digital twin is an exact replica of something in the physical world, be it an object, a process, or even an organ in the human body. It is a virtual representation that is intended to improve or provide feedback to the real version. The combination of artificial intelligence (AI), the Internet of Things (IoT) and data analytics has created digital twins that are constantly learning and improving through connection with physical sensors.

This type of preview captures detailed information about the physical characteristics, behavior, and performance of an object or system. And therefore, this information is used to simulate and analyze scenarios, predict results and optimize performance in a virtual environment.

The types of digital twins

There are several types of digital twins, which vary according to the production stage in which the object or process is:

Digital twin prototype: It is created before the physical product goes on the market, which allows and analyzes in detail how it would behave in reality.

Digital twin instance: It is created even when the actual product already exists, and is mainly used for testing in different environments and what-if scenarios.

Digital Twins Aggregate: It is based on collecting data from a real product to predict and analyze its capabilities and performance.

Additionally, digital twins can be categorized based on what they simulate:

Digital twins of processes: They replicate and simulate complete production processes, making it possible to identify possible failures and optimize efficiency. These digital twins focus on the representation of processes and operations. For example, in the manufacturing industry, they are used to simulate and optimize production flows, identify bottlenecks, and improve overall process efficiency.

Digital twins of systems: They create digital representations of complete production lines, which facilitates the detection of problems and the design of more efficient processes, which is very important for industries.

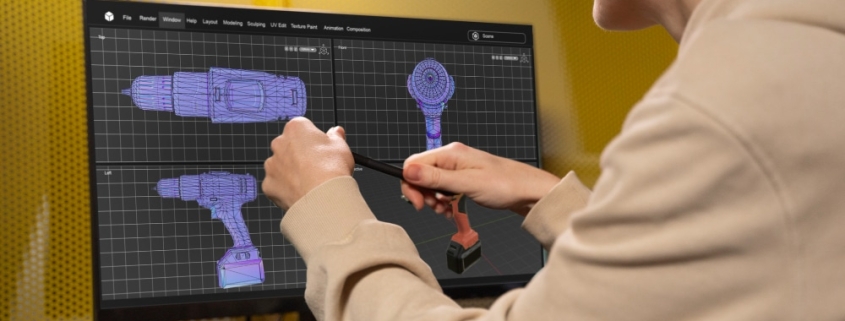

Product digital twins: These digital twins represent physical objects, such as machinery, equipment, vehicles, or final products. They capture detailed information about the physical and functional characteristics of these objects, allowing simulation of their behavior, performance testing, and optimization of their design and manufacturing.

Performance digital twins: These digital twins are used for monitoring and analyzing the performance of a system or equipment in real time. They capture data in real time on variables such as temperature, pressure, vibration, energy consumption, among others. They also allow detecting anomalies, predicting failures and performing predictive maintenance to avoid downtime and optimize operational efficiency.

Benefits of digital twins:

When asked about what are the benefits of digital twins, it turns out that by faithfully reflecting the properties and behavior of the original object or system, digital twins allow users to interact with them safely and carry out tests, experiments and improvements without affecting the actual object. They also offer the ability to perform virtual tests and experiments, which reduces costs and risks associated with experimentation in the real world. Other benefits of digital twins are as follows:

Optimization and efficiency: Digital twins allow detailed performance analysis and optimization of complex processes, since by simulating different scenarios and evaluating their impact in real time, digital twins help improve operational efficiency and maximize the performance of physical systems. This is especially valuable in sectors such as manufacturing, energy, transportation, and logistics, where performance optimization can lead to significant cost savings and improve competitiveness.

Informed decision making: They provide detailed and accurate information about the behavior of physical objects, allowing you to make decisions based on data analysis with greater confidence.

Cost reduction: Because digital twins prevent errors early, costly repairs and lost production can be avoided, resulting in significant savings. This is because virtual testing and optimization can be done before investing in production or physical deployment.

Accelerated innovation: Digital twins experiment and test different what-if scenarios, which drives innovation and the development of new products and processes. By providing a safe environment for testing concepts and making iterative improvements, digital twins encourage creativity and exploration of innovative solutions. In addition, they facilitate collaboration between teams and organizations by providing a common platform to share information and work together on the optimization and improvement of products and processes.

Predictive maintenance and reduction of downtime: They play an important role in the maintenance and repair of equipment and machinery. By constantly monitoring the performance of physical assets and comparing it to their digital replica, anomalies can be detected and preventative maintenance scheduled, avoiding costly downtime and extending the useful life of equipment.

In the energy sector, digital twins optimize power generation and distribution, improve the efficiency of renewable energy systems, and predict and prevent potential infrastructure problems. In the natural resources industry, such as mining and oil and gas extraction, digital twins are used to simulate and optimize operations, which decreases environmental impacts and improves worker safety.

As science advances and new tools and algorithms are developed, digital twins become even more sophisticated and precise, for which it is necessary to have the best experts in the sector to search for the best solutions and digital tools that use this technology.