Industry 4.0 in food production

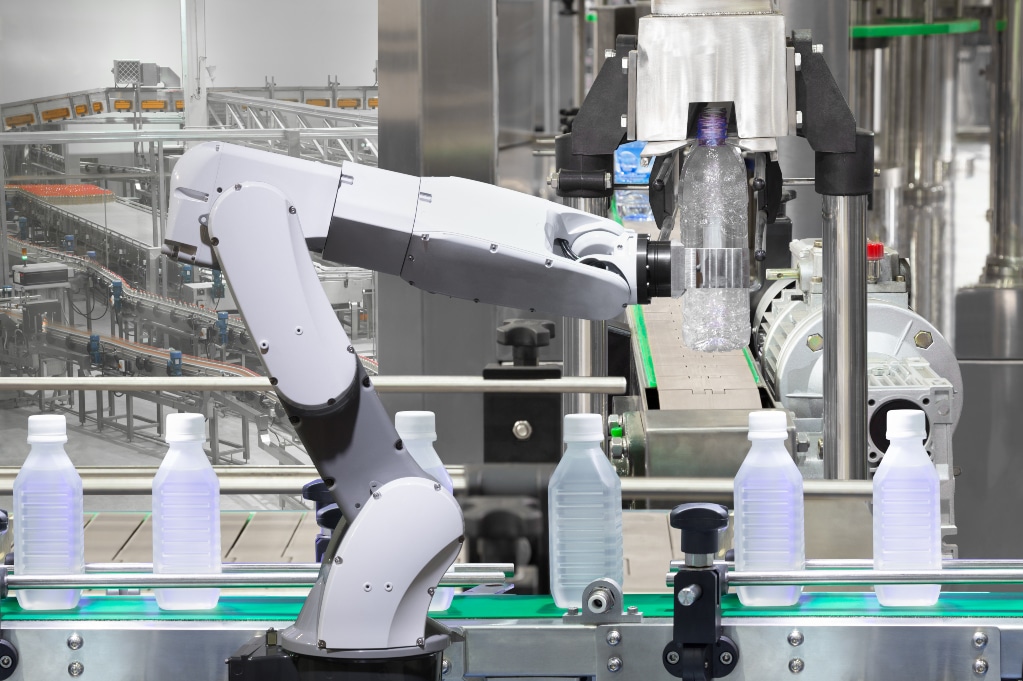

Industry 4.0 is also offering important advances in the world of food production and distribution. Also known as Food Industry 4.0, it is distinguished among other aspects by an advanced manufacturing with higher volumes of food, which occurs through technologies such as the Internet of Things, Big Data, automation and control software, to mention some of the advances that are essential to understand the revolution that is taking place.

Vertical networks of intelligent manufacturing systems, horizontal integration through manufacturing and logistics coordination, virtualization and integration throughout the entire supply chain, and exponential technologies are discovering new paths to the new manufacturing plant of the food industry.

Taking into account the aforementioned, one of the most useful ways to understand how Food Industry 4.0 is influencing, is to point out where some of the most significant changes that are taking place are seen.

Product recall

Food and beverage recalls may be necessary due to either consumer complaints or food inspections. Over time, pressure has grown on manufacturers to institute product recalls as soon as possible. However, the traceability of contamination is a complicated matter, as several factors must be taken into account such as microbial impurities, labeling and packaging errors, contamination by metals, plastic, glass or potentially dangerous substances such as oil. production machines or biological hazards. Therefore, processes must be implemented to identify and eliminate the sources that lead to errors.

Sensor technologies contribute greatly to this necessary effort. There are several varieties of smart identification systems that allow better traceability. For example, radio frequency identification (RFID) tagging tracks crops from harvest in order to trace the origin of the cargo. There are also other systems that allow systematic and efficient data tracking from raw material to final product.

New consumer behaviors

Today’s consumers gather information about products in the palm of their hand with smartphones and often select them based on the nutrients they want to have in their diet. Therefore, to motivate consumers to buy their products, manufacturers and sellers must choose point of sale solutions that allow them to influence purchasing decisions in the store itself.

One of the emerging technologies is that which has to do with smart labeling. The combination of wireless labeling, software applications and cloud platforms enables consumers to scan product labels with their mobiles to ensure product authenticity or obtain information on ratings, customer loyalty programs or product videos. You just need a device that has NFC connectivity. The data that these smart tags provide to manufacturers contains demographic information, location, interactions shared on social media, and the data that is extracted from the tags.

Likewise, it is also investing in testing strategies such as extending the shelf life of fresh produce or minimizing food and packaging waste.

Data management

Optimizing data collection and sharing throughout the product chain allows not only quick access to essential data, but also ensures that all process steps are securely documented. Data management is the sum of all parts, and for each part, this technology offers a very positive present and prospects. In this way, for example, the use of the Cloud helps manufacturers to provide data related to one or even thousands of products to use in their analysis.

The production of unique units

While single-unit production to meet customer custom orders has been difficult to implement until recently, companies are already moving in that direction as well, thanks to technical innovation. The possibility of automation and the sensor technologies mentioned above allow customization according to customer requests.

Challenges of Food Industry 4.0

Industry 4.0 is changing the landscape of the food and beverage industry. And with the market feeling saturated, manufacturers face huge challenges like the following.

-

Keeping labels clean without compromising taste

Obesity is one of the great health problems of our times. And the correlation between sugary foods and obesity is more than proven. For companies that produce products such as soft drinks or baby food, for example, reducing the sugar content has become a top priority.

The enormous challenge this presents, however, is reducing the amount of sugar while maintaining the sweetness and flavor of the products. R&D is focused on finding natural ingredients that retain the same familiar taste, but can be marketed as clean labels to meet the needs of consumers demanding healthy nutrients.

-

Harmonization of legal standards

Food regulations are constantly changing. Beyond the fact that laws and regulations are not always consistent, manufacturers also face the challenge of meeting the growing demands of an increasingly well-informed customer base. If manufacturers cannot ensure strict supply chains and a robust food safety management system, the risk of subsequent product recalls is high. Automated and transparent processes, along with streamlined workflows, ensure efficient data management and an improved quality control system.

-

Increased specialization

Another fact that is taking place is that consumers today are faced with an excess supply of products. The wide range of options is overwhelming and leads to a decreased willingness to consume, coupled with a greater desire to buy organic and healthy products. Food manufacturing companies must develop strategies to stand out from their competitors. Food production companies must find unique outlets that provide a distinctive competitive advantage and add value. There are a number of things you can do about it, from clean labels or environmentally friendly packaging to true commercialization of your company’s sustainable values.